-

Mobile Version

Scan with Mobile

- Member Center

291

291

The main function of the bearing is to support the mechanical rotating body, ensure the working position and accuracy of the shaft and its moving parts, reduce friction and wear, and bear the load. In daily application, the assembly of bearings generally needs professional operation guidance or experienced bearing engineers. The following small series will introduce the common bearing assembly methods and skills

Common assembly methods of bearings

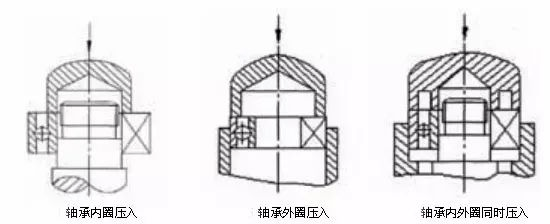

1. Percussion method: when the fit interference is small, the hand hammer can be used to percussion and install the bearing; The method is to put the copper rod or soft iron and sleeve on the inner or outer ring of the bearing, knock the copper rod with a hand hammer and install the bearing symmetrically.

2. Top pressing method: when the fit interference is large, press the bearing with a press, and put the sleeve when pressing. 3. Temperature difference method: when the fit interference is large, the temperature difference method can be used for assembly, and the temperature difference method of bearing can be used for assembly. During maintenance, the method of hot assembly is often used. The heating method is to use electric heater and oil bath for heating, among which the electric heater is widely used on site.

3. Temperature difference method: when the fit interference is large, the temperature difference method can be used for assembly, and the temperature difference method of bearing can be used for assembly. During maintenance, the method of hot assembly is often used. The heating method is to use electric heater and oil bath for heating, among which the electric heater is widely used on site.

Common problems and key links in bearing assembly

1. Preparation before hot assembly

The fitting size, diameter, boss, round root and chamfer of parts shall be rechecked, and the fitting surface shall be cleaned. Align the keyway of the shaft with the key to be fixed on the shaft. For oblique keys or tangential keys, use guide keys to ensure the mutual position of keyways. Before hot assembly, the retaining ring, gasket and other parts shall be repaired and trial assembled without error, and assembled after passing the verification.

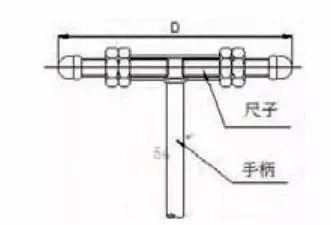

Alignment shall be made before hot assembly, and scribed marks and direction indication marks shall be made at the same time. The assembly surface is coated with lubricating oil to reduce the friction resistance during installation. Before hot assembly, a measuring ruler shall be made to measure and confirm whether the heated workpiece is heated to the assembly conditions. The ruler shall meet the conditions of light use and not easy to deform, and the thermal expansion of the measured part can be accurately measured at a distance from the heat source.

The ruler can be made of metal bar or metal plate, and the actual size shall be equal to the nominal size of the diameter of the measured part plus the maximum interference at the fitting part, and the minimum clearance necessary for fitting (its structure is shown in the figure).

After the heated parts are thoroughly heated, the measuring ruler can pass freely, and the heating can be terminated and the hot assembly operation can be carried out only after the re inspection confirms that the measured results are accurate.

2. Method of eliminating axial clearance in hot charging equipment

After hot assembly, due to the result of cooling shrinkage, axial clearance often appears at the axial positioning shoulder of the wheel and shaft. In essence, the assembly is not in place and the positioning is unreliable. Therefore, it is necessary to eliminate the gap in hot charging. Generally, impact method, bolt tensioning method and weight pressing method are adopted.

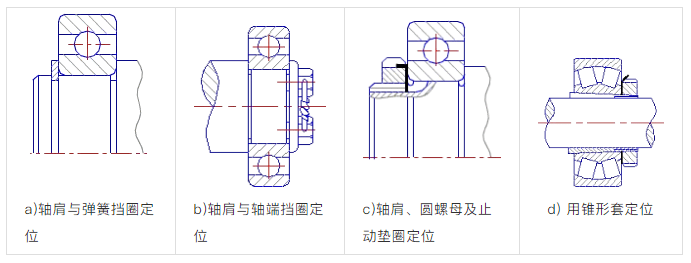

Method for positioning and fixing inner and outer rings of bearing

a) The shaft is embedded in the groove of the shaft with a retaining ring, which is mainly used when the axial force is small and the speed is not high;

b) The shaft end retaining ring fixed with screws is fastened, which can be used to bear large axial force at high speed, and the screws shall be provided with anti loosening measures;

c) It is fastened with round nut and stop washer, which is mainly used in the case of high speed and large axial force;

d) It is positioned with a conical sleeve and fastened with a stop washer and a round nut. It is used for bearings with conical holes on the optical shaft and inner ring.

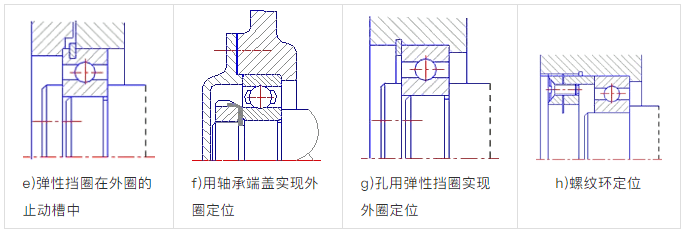

e) The hole embedded in the housing groove is fastened with a circlip, which is mainly used when the axial force is small and the size of the bearing device needs to be reduced;

f) It is fastened with bearing end cover, which is used for various centripetal, thrust and centripetal thrust bearings with high speed and bearing large axial force;

g) Insert the shaft circlip into the stop groove of the bearing outer ring for fastening, which is used when the housing is inconvenient to set a shoulder;

h) It is fastened with threaded ring, which is used when the bearing speed is high and the axial force is large, but it is not suitable to fasten with bearing end cover.

Axial fixation of inner and outer rings of rolling bearings

In order to prevent the bearing from axial movement relative to the shaft or seat hole when bearing axial load, the bearing inner ring and shaft, outer ring and seat hole must be fixed axially. The common axial fixing methods of inner and outer rings of rolling bearings are as follows: