-

Mobile Version

Scan with Mobile

- Member Center

399

399

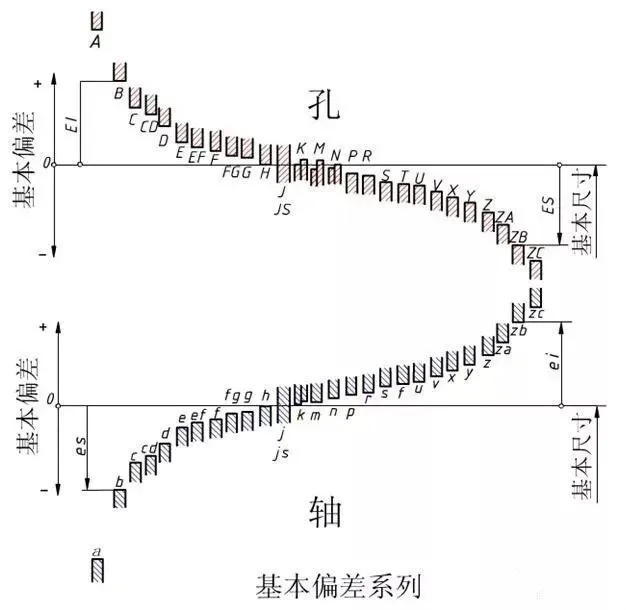

In our R & D and production, the processing and matching of holes and shafts are often involved. Three contents are often considered in the selection of tolerance and matching of holes and shafts: the selection of datum system, tolerance grade and matching type.

When the hole and shaft are matched, the selection of datum system will be comprehensively considered from the aspects of structure, technology and economy. It is generally considered from three aspects:

1. generally, the basic hole system is preferred. Because holes are usually harder to machine than shafts.

2. When matching with standard parts, the selection of reference system is usually determined by standard parts. This can better realize the interchangeability of products.

3. In order to meet the special needs of matching, it is allowed to use any hole and shaft tolerance zone to form the matching.

During hole shaft matching, the selection principle of tolerance grade is as follows:

1. For the higher-grade matching with nominal size of 500mm, the hole is difficult to process than the shaft at the same level. When the standard tolerance is it8, the national standard recommends that the hole be matched one level lower than the shaft. However, for the matching with standard tolerance > it8 or nominal size > 500mm, the hole and shaft matching at the same level are recommended because the measurement accuracy of the hole is easier to ensure than the shaft

2. Select the tolerance grade, that is to meet the design requirements and consider the possibility and economy of the process

3. Matched parts shall match

Interference transition or tight fit, precision requirements are not high.

There are three selection methods of coordination:

1. Calculation method: calculate the required clearance and interference according to certain theories and formulas

2. Experimental method: it has a great impact on product performance. For some cooperation, experimental method is often used to determine the best clearance or interference of machine working performance

3. Analogy method: according to the actual situation of the used cooperation in the same type of machine or mechanism verified by production practice, and considering the use requirements of the designed machine, determine the required cooperation by reference.